Cathodic protection, especially in metal-related business areas; It is an issue that companies that carry out shipping or oil exploration and extraction activities should pay attention to. After taking the necessary precautions for cathodic protection, you can get a cathodic report. In this way, you will not have to worry about the cathodic report requested in some areas.

Well, let's take a look at the answer to the question of what is cathodic protection… cathodic protection; It is known that metals corrode over time as a result of the reaction with water or air. Thanks to cathodic protection, it is possible to prevent this situation. Wearing and rusting of metals can be prevented by regular cathodic protection.

When the cathodic is made, more active metals are placed next to the metals that do not want to be corroded. The more active metals are, the more they are willing to react. In other words, when both air and water come into contact with metals, the metals you want to protect will not react, but the active metals will react. In this way, metals will have a longer life as a result of cathodic protection.

At this point, the following question may come to mind; How is cathodic measurement done? Is there a certain standard or can everyone have cathodic protection and get a cathodic report as they want? Of course not… The standards that are valid in this regard have been set by TSE and the report to be prepared will be arranged according to whether the TSE standards are fulfilled or not.

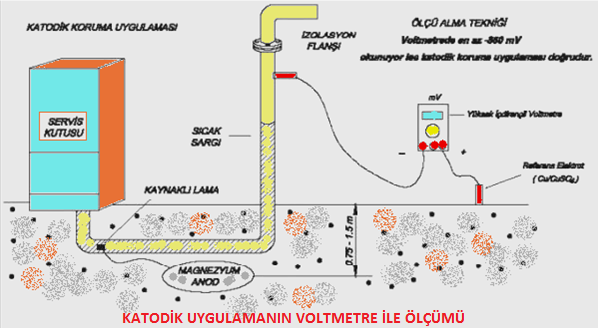

Cathodic protection is implemented in two different ways. While the first of these is cathodic protection with external current source, the second is cathodic protection with galvanic anode system.

Of course, some conditions must also be met for cathodic protection… Electricity must be transmitted uninterruptedly in the pipeline where cathodic protection will be made. Especially in pipe joints, there can be a problem in this regard. If such situations occur, conductors that will provide electrical transmission should be added to the pipe joints. It is extremely important that the pipeline is insulated from other metals. The two cathodic structures in the pipeline must also be electrically isolated from each other.

In addition to all these, after the cathodic protection to be applied, the potential difference should be checked regularly every six months. Remember; If cathodic measurements are not made regularly, the required efficiency will not be obtained.