It was founded in 1975 by two brothers, Ahmet Mithat ERTUĞ and Hüseyin Münip ERTUĞ, in Demir Sanayi, under the name ERTUĞLAR, on an area of 90 m². It changed its title to EMGE KOLLEKTIF ŞİRKETİ ELEKTRO MECHANİK GEREÇLER ENDÜSTİSİ in 1981 and to EMGE ELEKTRO MEKANİK GEREÇLER ENDÜSTRİSİ A.Ş. in 2018. changed to.

It carries out its production in a 7300 m2 closed and 10.000 m2 open area with a total of 170 qualified employees, including 30 engineers, and contributes to the national economy. Emge, which has been serving the defense industry for more than 35 years and adopting continuous improvement as its principle, carries out six sigma and kaizen studies in this direction.

Emge, which opened up to the world from Ostim, contributes to domestic and national production with its membership in the Ostim Defense and Aviation Cluster, a joint action formed by SMEs that come to the forefront with their high competitive power and produce goods or services in the defense and aerospace sectors.

EMGE, ASELSAN A.S. VE TUSAS A.S. is the approved subcontractor of FNSS, ROKETSAN, KALE HAVACILIK, HAVELSAN, HAVELSAN TEKNOLOJİ RADAR, KAREL, SAVRONİK, TÜBİTAK, SELEX, AYESAŞ, ASPİLSAN and ZODIAC AEROSACE.

Continuing its production with the investments it has made in the technological field and new equipment supplements, Emge has AS9100, ISO 9001, NATO and National confidential facility security certificate, and TSE certificates.

Our company, which appeals to the defense aerospace, electrical and electronics, LED lighting and electro-mechanical sectors, has a large machinery park with high technology. It carries out machining with high precision and technology CNC milling, CNC sliding automat, CNC lathe and CNC mill turn machining centers.

The plastic injection department, which has been in it for more than 40 years, has a plastic injection capacity from 1 gr to 1.5 Kg. It can also design and manufacture plastic injection molds. In the ultrasonic welding workshop, the process of sticking plastic to plastic and nailing metal to plastic can be performed with the ultrasonic joining method.

It checks whether it meets the desired level by measuring the manufactured products with the latest technology and high precision measuring equipment such as CMM. All these measurement and calculation processes are successfully implemented in the production network.

Using its advanced test infrastructure in processes such as vibration and shock testing, air conditioning testing, power input testing and life testing, Emge also provides services with SMD typesetting line, Coiling Workshop, Vacuum casting and screen printing & pad printing workshops.

For the last 7 years, it has made significant investments in the localization and development of strategically important products, especially in the defense and aerospace industry. As a result of these investments, Aselsan A.Ş. It also contributes to the defense and aerospace industry with its slip ring drum, Ignition solenoid and infrared LED lighting products used in many strategic projects it has produced for

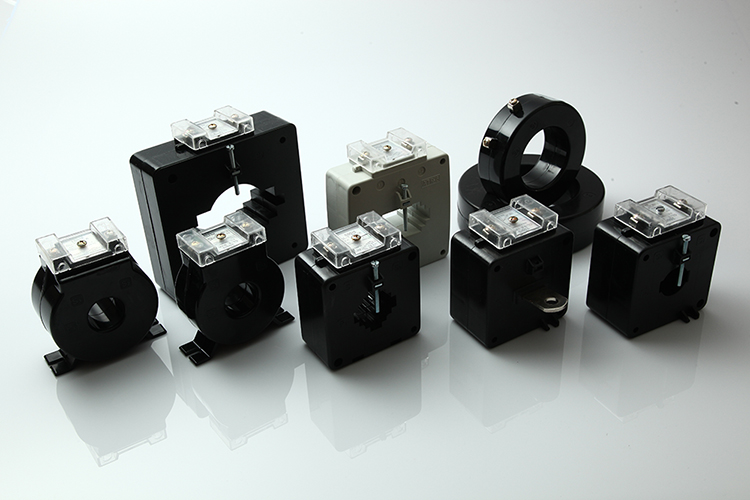

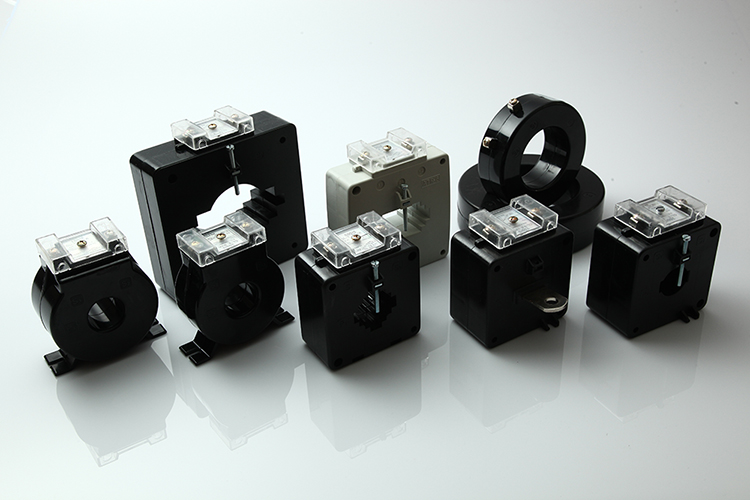

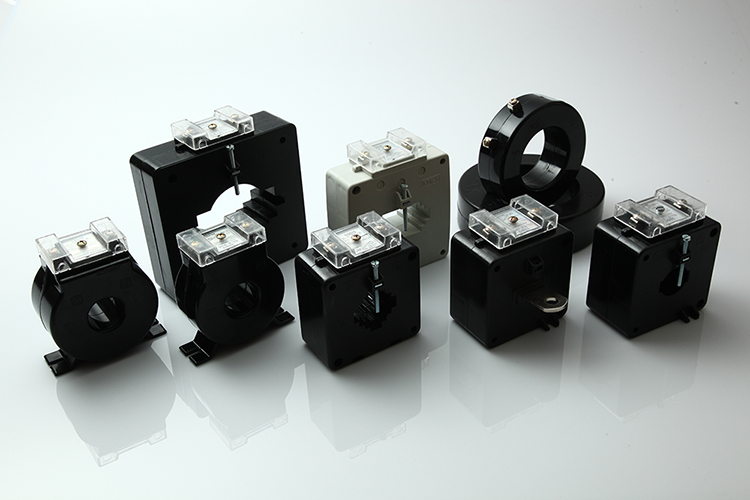

Under the EMGE brand, it continues on its way by adopting the understanding of domestic and national production with the production of analog and digital panel type measuring instruments, low voltage current transformers and safety equipment with a 97% domestic rate.