Karaduman Makine üretimi olan YARI otomatik küp şeker presleme ve paketleme makinaları toz şeker belirli oranda su ile karıştırılıp yüksek oranda presleyerek küp şeker olarak bir paslanmaz çelik hazır bant' a dökülen bu bant üzerindeki preslenmiş küp şekerler kurutma DÖNER FIRINIDAN geçirerek tam otomatik kutu makinalarından kutu konveyörleri ile gelen kutuları dolum robotunda istenilen sıra halinde dolum yapmak suretiyle el değmeden dolduran ve sonra dolum robotundan çıkan dolu kutuların ağzını kapatıp yapıştıran ileri teknoloji ürünlü kendi kendini kontrol eden sistemlerle donanmış makinalardır. Gerek makinaların Karaduman makineye özgü kullanılan malzeme kalitesi, mükemmel işçilik, satış sonrası servis ve garanti hizmetler i uzun vadede kullanıcının daima takdirini kazanmıştır.

Tesis 6 adet birbirleri ile tam senkron olarak çalışan makinalardan oluşmaktadır.

Üretim Seyri

Şeker, besleme silosuna vibratörlü elek üzerinden doldurulan Toz şeker, besleme helezonu ile otomatik seviye kontrollü rezervuara sevk edilir. Buradan karıştırıcıya akan toz şeker, dozaj pompası tarafından püskürtülen belirli bir miktar su ile karıştırılarak toplama bölgesine aktarılır. Su ile karıştırılmış nemli toz şeker, presleme kafasına göre senkron devirle cebri kalıp yükleme kutusu aracılığı ile yüklenir. Tambur etrafına yerleştirilmiş kalıp pimi kalıba giren şeker miktarını ( gramaj ayarı ) ayarlayan ayar kamı üzerinden geçerek, presleme kamı tarafından pres kolu üzerinde şıkıştırılır ve nemli şekerin küp şeklinde kalıp preslenmesini sağlar. Piston şeker dökme kamı üzerinden geçerken kamın içindeki nemlenmiş şekeri çelik hasır bant üzerine bırakır. Kalıp pimlerinin alın yüzeyleri ıslak bir kıl fırça tarafından temizlenir. Nemli şekerler bant üzerinde kurutma fırınlarından geçerek üretim tamamlanır.

Barbüten

Mikser ‘den gelen nemlendirilmiş kristal şeker belirli bir devirde dönen tırmıklı miller vasıtasıyla şeker kalıplarına doldurulur. Ürün ile temas eden bütün yüzeyler paslanmaz çeliktir. Bar büten gıda kategorisine uygun malzemelerden imal edilmiştir.

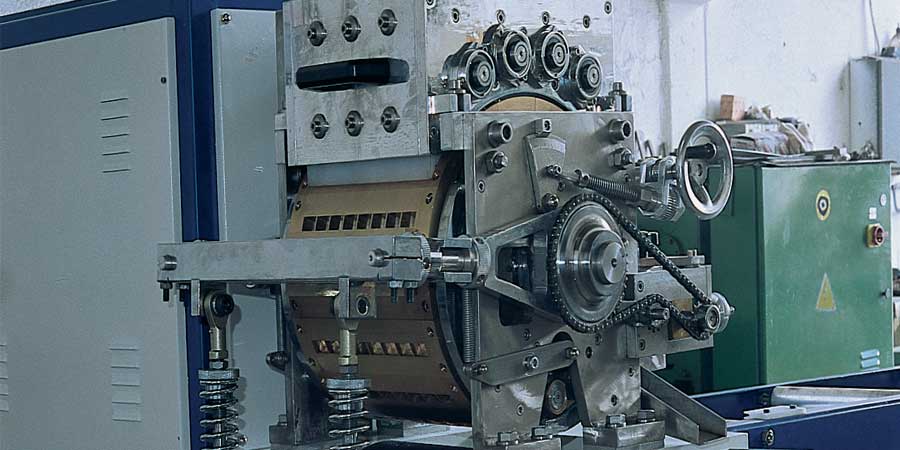

Tambur

Bar büten sisteminde kalıplara doldurulan belirli bir dozda olan nemli şeker tamburun kendi ekseninde kamlar yardımıyla dönerek istenilen gramajda ayar yapılabilinir. Tambur sisteminin üzerindeki preslerde nemli şeker sıkıştırılarak çekiçlerle paslanmaz çelik hasır banda sıra halinde dökülür. Portatif olan bu sistem tamamen paslanmaz çelik ve sert bronz alaşımlı malzemelerden imal edilmiştir.

Kurutma Fırınları

Tambur sisteminden düzgün sıralar halinde hasır paslanmaz çelik banda dökülen nemli küp şekerler kurutma fırınlarına girer. Bu fırınlarda şeker bünyesinde bulundurduğu nemi belirli bir oranda atar. Özel bir ısı transfer sistemi olan bu fırınlarda porselen rezistanslar kullanılmaktadır. Her bir fırının ısısının ayarlanabilmesi mümkün olduğundan, kurutma aşamasında şeker özelliğini bozmadan istenilen nemliğin %50 si sağlanmaktadır. Bu fırınların toplam uzunluğu min. 30 m max. 40 m dir. (15 metrede kurulan tesislerde özel bir sistem olan döner fırın kullanılmaktadır)

Soğutma Fırınları

Kurutma fırınlarından çıkan küp şekerler özel bir operasyonla % 70 – 80 oranında nemliği alınır. Kurutma fırınlarından çıkan küp şeker soğutma fırınlarından 30 C civarına da çıkar. Kurutma operasyonları biten şekerler konveyör sonunda ki dolum robotuna gelerek operasyona hazır hale gelir.