EnergyComp

Auditing your compressed air system needs; expertise in compressed air systems, acquiring big data, reading and analyzing those data and reporting actual condition. Then adding/removing items, changing pressure bands etc. Means a lot of work to do. Besides if it seriously applied, minimum of 30 million of data to analyze we are talking about. Do you think that this could be done by an expert having Excel spread sheet in one hand? No way! This amount of data should be analyzed precisely to find the optimum solution for your system. That’s what EnergyComp does!

How it works?

We integrate our expertise on compressed air systems into this software. Our engineers install sensors, dataloggers to your system to acquire your compressed air system data for minimum of 2 weeks. For larger systems like 1 MW of installed compressor power, we prefer 1 month. Every single second, data is recorded to these multiple loggers and at the end of the application engineers take this with them and insert to EnergyComp. This was the hardest work done! The rest is in EnergyComp’s hand, analyzing, reporting, finding optimum combination, adding/removing compressors etc.

Simply EnergyComp Does:

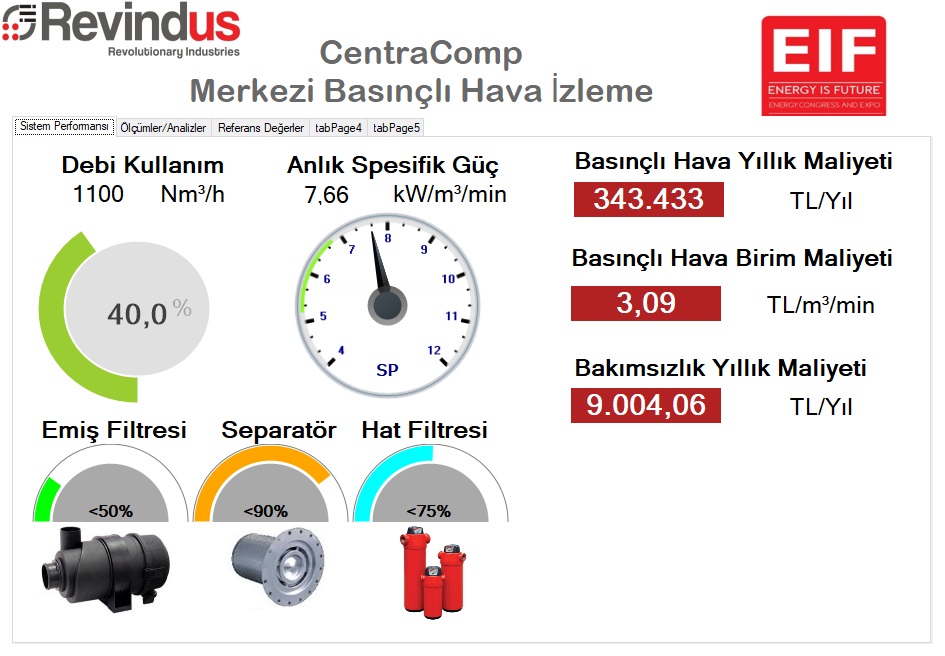

- Measure: By sensors integrated to your system

- Acquire: By dataloggers

- Analyze: By EnergyComp within minutes

- Enhancements: Quick maintenance and potential savings

- Simulation: Optimum solution for your system according to unique algorithm

- Reporting: Including actual case, L/NL conditions, leaks, enhancement and simulation comparisons