How it works?

Simply, thanks to compressible flow dynamics and special geometry of the nozzle, the velocity of the gas reaches to speed of sound (Mach1) at the throttle. At this condition flow is “CHOCKED” in the other terms limited. Therefore, no further flow rate is allowed to flow through.

Unique Design for Every Application

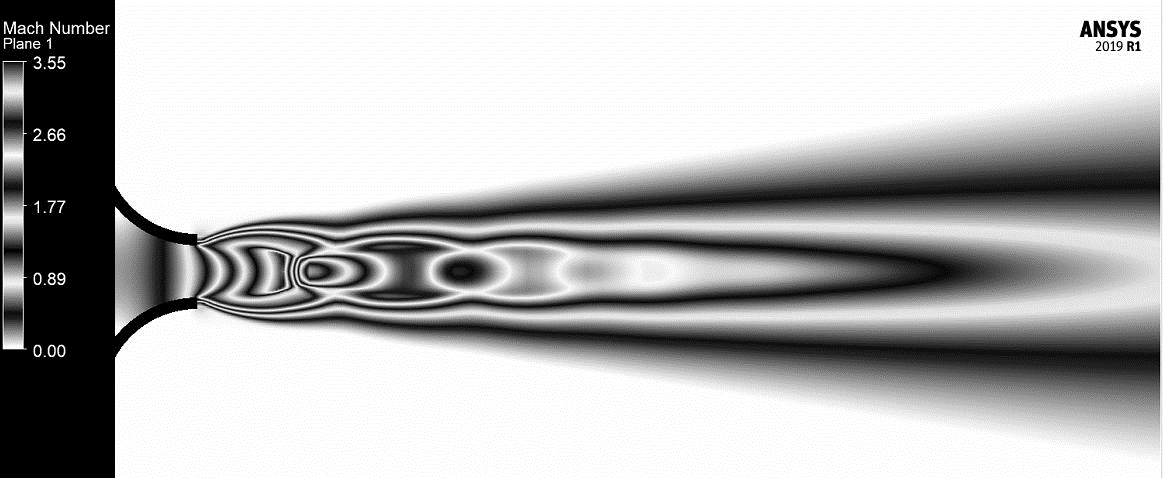

Every application has its own requirement. The gas, pressure, flow rate and other conditions may vary. Therefore, Revindus designs the nozzles with help of their experience on compressible flow dynamics and powerful CFD package tool ANSYS FLUENT via ANSYS STARTUP Program for each application. The unique design enables the nozzle to recover pressure effectively for use.

Manufacture for Precision

The flow rate is related to throat geometry and the surface. For each application, the surface quality and material might differ. Stainless steel and aluminum are the most popular sonic nozzle base material.

Applications

- Compressed air/gas header branches where different flow rate is required

- Just after the desiccant dryers to make sure the granules are safe

- Parallel connection of equipment (like dryers)

- Flow Computers

- Calibration of flow meters

- Limiting the flow rate

- Testing under stable and certain flow rate

SONIC NOZZLE FLOW COMPUTER

For accurate, precise and repeatable flow measurement, all you need is a Revindus Sonic Nozzle Flow Computer. The flow computer is simply a multi-discipline engineering gem. Designing-manufacturing the nozzle, metering pipes, flow straighteners, sensors, flow computer hardware (electronics), communication and software. All done in house, none of the outsource is needed to complete the project from start to end. Therefore if you require any special item, YES , we can do it fast!

Nozzles

The nozzles are designed and manufactured precisely for this application. Thanks to high tech CFD package and Revindus special design software, nozzles are adequately selected for your requirements.

Electronics and Sensors

All sensors are integrated into the flow computer case. So, no need to wire 24VDC with 4-20mA sensors all across the flow metering system. RTD sensors are fit in the system directly. Thanks to modular design of electronic boards, any type of sensor/system can be integrated to the system easily. Universal serial RS485 connection through USB is used for safe and fast data transfer to software. According to your requirement, precision of the sensors can be changed.

Software

Click and measure software is our strength on this product. Completely unique algorithm enables this software to acquire and handle data, to calculate the flow reading precisely within milliseconds. Besides, datalogging, checking for stability, online graphs, SI/US unit selection, Intranet/Internet data transfer is standard!

Advantages

- Internationally Recognized

- Real Mass Flow Reading

- Long Term Accuracy and Repeatability

- No Moving Parts

- No Differential Pressure Reading

- Wet/Oily Gas Reading

- Robust and Heavy Duty

- Downstream Has NO Effect on Flow Rate

- ±0.7% to ±0.15% reading accuracy can be achieved

- Repeatability can be low as down to ±0.15%

Applications

- Compressor Performance Acceptance Test(ISO1217:2005)

- Gas Flow Meter Calibration

- Gas Turbine Engine Component Gas Passages Calibration

- Automotive

- Valve CV Testing