TD – Teleskobik Dikme (Demir Direk):

Teleskobik dikme standart imalat ölçülerimiz:

- 175-300cm. çalışma aralıklı direk

- 200-350cm. çalışma aralıklı direk

- 225-400cm. çalışma aralıklı direk

Teleskobik Dikme Standart Teknik Özellikler

- Dış boru (60×2,5 mm) dir.

- İç boru (48×2,5 mm) dir.

- Üst pabuç 4 mm dir.

- Alt pabuç 4 mm dir.

- Sap-kanca 12 mm dir.

- Mekanizma 7 hadvedir.

- Somun sferodur (GGG 50).

- Anti pas boyalıdır.

- Borular ISO ve TSE belgelidir.

- Teleskopik dikmelerde değişik ölçülerdeki imalatlar siparişle yapılır.

- Teleskopik dikme, demir direk üst başlıkları kullanım yerine göre değişir. Döşeme için 10 cm ‘U’ şeklindedir.

- Geniş döşemelerde bazı teleskobik dikmelerin altında üç ayak sehpa kullanımı dikmeyi kendiliğinden ayakta tutar, montaj kolaylığı sağlar, rijitliği artırır.

- Teleskobik dikmelerin dişli kısmının yanık yağıyla yağlanması tavsiye edilir.

- Teleskopik dikmelerin taşıyıcı özelliklerini dişli kısmında kullanılan malzeme ile döküm somunun kalitesi belirler.

Güvenlikli iskele için en uygun sistem flanşlı iş iskelesidir. Sıva iskelesi, tijli duvar dayamanın sıkça kullanılmasıyla daha güvenli iskele haline gelir.

H tipi iskele elemanlarının iki H’ı birbirine bağlayan çaprazları çok zayıftır. Çaprazlar dışında iki H birbirine metal kalaslarla bağlanır. Dolayısıyla yük taşıyıcılığı azdır. Bu nedenle H sıva iskelesinin ara mesafesi 3 m yapılamaz. En fazla 250 cm yapılır. Buna rağmen üzerindeki çelik kalasların sayısı arttıkça, (ki bir iş iskelesinin güvenlikli olması için metal kalas her katta olmalıdır) iş iskelesinin taşıyıcılığı azalır. Biraz sert bir rüzgârda çökebilir. Rüzgâr etkisini azaltmak için sıva iskelesinin dış tarafı branda ile kapatılmayıp, boş bırakılmalıdır. Sonuç olarak yüksek katlarda H tipi iskeleyi kullanmak, tijli duvar dayama sayısını ve iş iskelesinin çökme riskini artırır. Bir sıva iskelesinin güvenli hale gelmesi için sadece tijli duvar dayama kullanılması yetmez. Çalışılan her katta yani iş iskelesinin her 2 metresinde 2 adet çelik kalas konulmalıdır. Metal kalas da denilen çelik kalasların konulduğu her yerde, işçi korkuluğu denilen iskele korkuluğu olmalıdır. İskele korkuluğu olan her yerde tekmelik denilen ve çelik kalaslardan 15 cm yükseklikte bir koruyucu olmalıdır.

Ayrıca mümkünse binanın her yüzünde veya iki yüzü için tek sıra iskele merdiveni olmalıdır. Bu merdivenlerin basamaklarının ayak bastığında kaymaması için, baklavalı sac olması tercih edilmelidir. Sıva iskelesi merdiveninin basamaklarının kutu profil olması riski artırır. Sıva iskelesinde merdivenleri aşağıdaki şekilde görüldüğü gibi güvenli olmalıdır. Gemici merdiveni şeklinde olması – iş güvenliği uzmanlarınca kabul edilse dahi- çalışma sırasında ve yukarı katlara malzeme aktarılmasında kaza riskini artırır.

Dolayısıyla güvenlikli iskele için güvenli iskele merdiveni ve güvenli iskele korkuluğu kullanılmalıdır.

Sıva iskelesinde kullanılan bütün bu malzemeler, iş iskelesinin üzerine daha hiçbir malzeme konulmadan sıva iskelesine fazlasıyla ağırlık verir. Bu nedenle sıva iskelesi elemanları öncelikle kendi ağırlığını taşıyacak nitelikte olmalıdır.

Sıva iskelesi üzerindeki yükleri azaltmak için ilk yapılacak şey, çelik kalasları hafifletmektir. Ancak metal kalasları hafiflettikçe esnemeleri artar. Metal kalasın üzerinde çalışan işçiyi korkutur. Hattâ çelik kalas üzerine sıva vb ağır malzeme konulduğunda kırılma riski artar.

ELDEKİ FLANŞLI İSKELELERİ GÜVENLİKLİ İSKELE HALİNE GETİRMEK

Bilindiği gibi, ülkemizde milyarlarca TL değerinde sıva iskelesi mevcutta vardır. Bizim gibi bir ülkenin bu iş iskelelerini hurdaya çıkarması çok yanlış olur. Belki de bu nedenle iskelelerden sıcak daldırma galvaniz şartı geçici olarak kaldırıldı.

Firmamız ülkemizin ekonomisine daha fazla katkıda bulunmak için eldeki flanşlı sıva iskelelerine verdiği ilave iş iskelesi elemanlarıyla güvenlikli iskele haline gelmesini sağlamaktadır.

Güvenlikli iskele elde etmek için mevcut flanşlı iskeleye verilen ek elemanlar şunlardır:

Güvenlikli iskele merdiveni

Çelik kalas (metal kalas)

İskele korkuluğu (işçi korkuluğu)

Tekmelik

ÇELİKSAN TİPİ FLANŞLI İŞ İSKELESİ

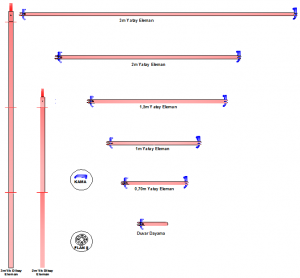

Sıva iskelesi Dikey Eleman;

-Teknik özelliklere uygun 48 mm çapında, 2,5 mm et kalınlığında borulardan imal edilmektedir. Ancak güvenlikli iskelelerde 7 kattan daha yüksek binalarda kullanıldığında et kalınlığı 3 mm olmalıdır.

-Flanşlar yük taşıma niteliği göz önünde bulundurularak 7 mm sacdan yapılmaktadır.

-Dikey elemanların ara bağlantılarında 30x30x2 mm kutu profil kullanılmaktadır.

Sıva iskelesi Yatay Eleman;

Teknik özelliklere uygun 48 mm çapında, 2,5 mm et kalınlığında borulardan imal edilmektedir.

Kurt ağzı borulara açılmaktadır. İstenildiğinde fiyat farkı verilerek 4 mm malzemeden yapılan kurt ağzı kaynatılabilir. Ancak verilen bu fark, boru uçlarındaki ezilme maliyetinden daha fazladır.

5 mm kamalar iş iskelesi yatay elemanı üzerindeki ilk küçük deliğinden geçtikten sonra şişirilir. Böylece pimli yani kamalı sistemde en çok karşılaşılan kamanın kaybolma riski azaltılır.